Industrial scales provide different benefits and facilitate certain processes inside warehouses and industries where weight dictates results. Weight can help determine price, manufacturing processes, transportation best practices, and vital details that matter for safety.

Every machine, no matter the size, requires different maintenance procedures to achieve reliable results and avoid errors when handling products. These 10 reasons a digital scale can give you fluctuating weights will help you understand and reduce errors.

Simple practices will have positive results in your daily practices, minimizing inaccuracy and improving the overall performance of your business. Having fluctuations in your results could affect you and everyone involved in the process, and this issue could eventually develop into dangerous practices.

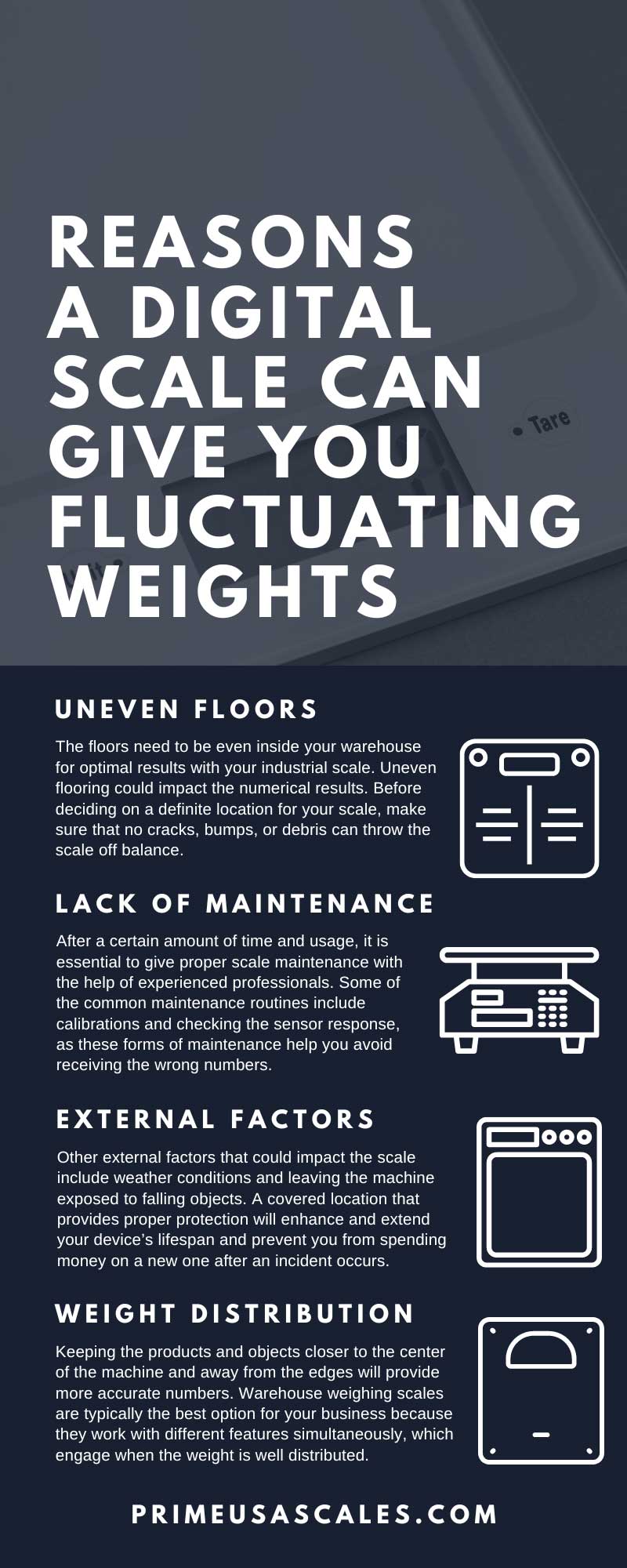

Uneven Floors

The floors need to be even inside your warehouse for optimal results with your industrial scale. Uneven flooring could impact the numerical results. Before deciding on a definite location for your scale, make sure that no cracks, bumps, or debris can throw the scale off balance.

Adding anything underneath the device to balance it with the floor could cause damage, produce inaccurate results, and potentially break the scale. A polished, level surface will give you the best results, especially when you place the scale in a large, open space.

Lack of Maintenance

After a certain amount of time and usage, it is essential to give proper scale maintenance with the help of experienced professionals. Some of the common maintenance routines include calibrations and checking the sensor response, as these forms of maintenance help you avoid receiving the wrong numbers.

Simple maintenance routines such as keeping the scale clean, moving it as little as possible, and storing it in a safe location are crucial to maintaining the scale’s condition. These machines are strong and reliable, but they also need your help to deliver better performance.

External Factors

Keeping the scale clean will prevent dust and debris from accumulating inside and under the sensors, which could create an imbalance. These factors are two of the most common ones that you can prevent with daily cleaning practices.

Other external factors that could impact the scale include weather conditions and leaving the machine exposed to falling objects. A covered location that provides proper protection will enhance and extend your device’s lifespan and prevent you from spending money on a new one after an incident occurs.

Weight Distribution

Keeping the products and objects closer to the center of the machine and away from the edges will provide more accurate numbers. Warehouse weighing scales are typically the best option for your business because they work with different features simultaneously, which engage when the weight is well distributed.

One object is simple to align, but weighing multiple objects at once could become challenging if the distribution is uneven or not centered. Always aim for the center, load the scale with the heaviest items in the middle, and move your way outwards to avoid any issues.

Battery Problems

For any device or machine that works with batteries, there are visible signs that occur when the batteries are running low. If your scale takes more time than usual to turn on or the numbers flicker, you need to check the batteries. These issues indicate that it is likely time to replace them.

Leaving your scale outdoors, especially in cold temperatures, will quickly drain the battery. A low battery could result in the machine giving you different numbers each time. Before using your scale, check that the power is constant; if it’s not, check the batteries; if the battery is rechargeable, ensure the lithium battery doesn’t have any leaks and that it has a solid power connection.

Sensors Failing

Industrial floor scales can work with multiple sensors, depending on the size and capacity they must work with. These sensors require monthly maintenance to avoid fluctuating weights in your digital scale, which professionals can do quickly for you. They may also replace any damaged sensors.

Overloading the scale and lack of cleaning are two of the main reasons why sensors fail. When one sensor is not doing its job, it’s nearly impossible to get accurate results. The rate at which sensors fail may also change depending on how much you use your scale and what kind of weight the sensors bear.

Water Damage

Locations with recurrent rain or snow must have the proper protection and maintenance to prevent water from damaging the machine. Most industrial scales work with stainless steel, which makes them resistant, but water could seep into the digital machine and cause problems.

It’s essential to dry the scale immediately after it comes in close contact with liquids. When possible, keep the scale under a roof, and if you need to store it, keep it above ground on a strong shell with a protection cover. It’s also beneficial to remove the battery when you store the scale.

Lack of Calibration

The calibration process ensures that the scale is at zero when nothing is on the main platform. With time and usage, digital scales could loosen up and provide measurements despite the non-existent weight on top.

Different features allow you to subtract added weights from containers or objects that should not appear in the final numbers. This feature is ideal for light or small objects, but a lack of calibration will make it confusing and inconsistent for the user.

Signal Interference

Digital scales work with different features, such as Bluetooth connectivity and Wi-Fi, that could interfere with the signal and connections of the scale. Using phones close to the scale, especially if you receive results straight to your phone via email or a text message, may not be ideal.

Before using your scale, keep electronic devices away to decrease the chances of seeing inaccurate numbers. This issue is not common, but if nothing else seems to be the answer, you should test to see if interference is the cause.

Damaged Scale

Working with heavy-duty machines and heavy products could damage your scale without you noticing anything physical problems. These forms of damage could occur when an object hits the scale with enough strength to break it or damage the computer internally.

Maintenance routines are essential because they will prevent any other problems from developing that could damage your business’s performance. Any time you need help with a scale, it’s best to reach out to professionals that can improve your practices and manage any specific situations.

If you want to deliver better results and maintain your scales, you can schedule preventive maintenance and repairs or choose from a wide variety of products from Prime USA Scales. Working with professionals with the right experience and expertise will elevate your business and increase your productivity. Call us today to get more information about how we can help you succeed.