Businesses that rely on precise weighing quickly see why dust and water resistance is important for bench scales. Dust, moisture, and spills interfere with scale sensors, damage internal components, and shorten the equipment’s lifespan.

Companies handling food, chemicals, or raw materials can obtain reliable readings and results from scales designed to withstand these elements. Let’s explore the top reasons why dust and water resistance are key characteristics of effective bench scales.

Protect Accuracy in Challenging Environments

You’ll often find a benchtop scale in areas where dust, liquids, and fine particles exist, which can impact sensor accuracy. Even small amounts of contamination can affect the scale’s sensors and cause inaccurate readings. Water can corrode electronic components, and dust can clog delicate parts and trigger calibration issues.

Scales with proper sealing prevent these problems and keep measurements precise. Using equipment that resists dust and water delivers accurate, dependable readings for daily operations. These accurate readings allow workers to manage inventory, pricing, and quality control, all of which directly impact the bottom line.

Extend Equipment Lifespan

Equipment exposed to dust and moisture wears down faster. Corrosion, sticky surfaces, and sensor malfunctions shorten a bench scale’s lifespan. Businesses that use water- and dust-resistant bench scales limit their exposure to these risks.

Protective features help scales endure routine cleaning and minor spills, which cuts the need for repairs or replacements. Over time, this durability saves money and prevents workflow interruptions. Companies can rely on these scales for years and never sacrifice performance, making them a cost-effective choice for environments that demand clean, reliable operations.

Enhance Workplace Safety and Cleanliness

Scales that resist dust and water help workplaces stay clean and safe. Spilled liquids create slip hazards, and dust can irritate workers or contaminate products. Scales built to withstand these challenges help work areas maintain proper hygiene.

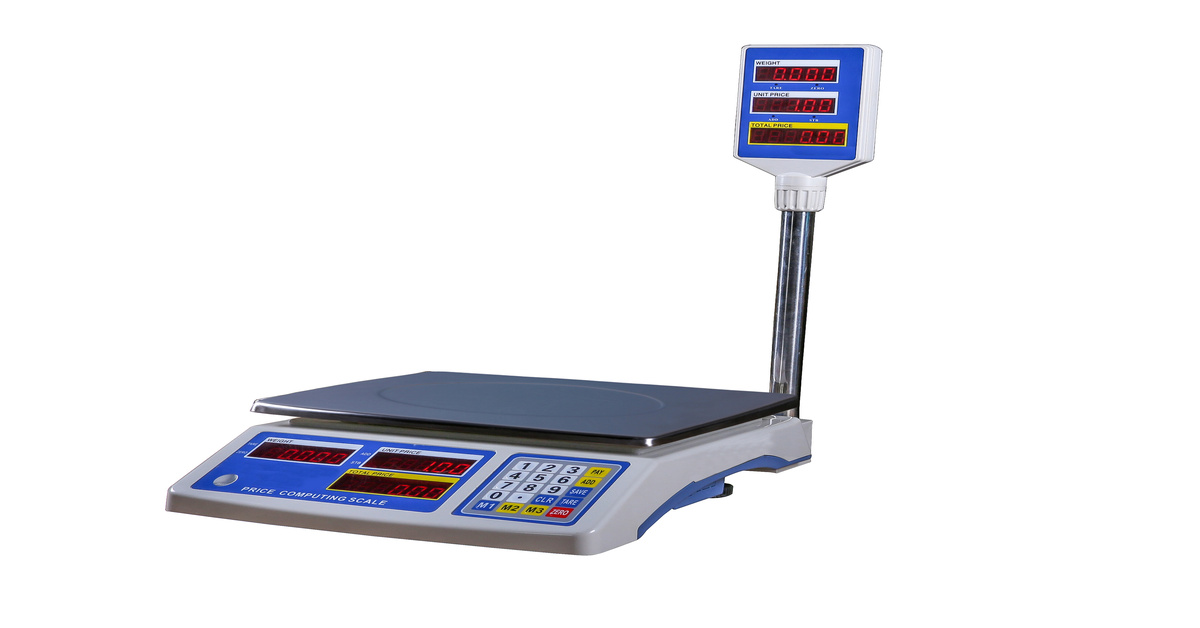

Many benchtop scales have smooth surfaces and sealed buttons, allowing employees to wipe them down fast and thoroughly. Workers can handle materials confidently because of bench scales that resist spills and debris. These features protect employees, make daily operations safer, and help businesses meet industry safety standards.

Make the Right Investment

Businesses understand why dust and water resistance is important for bench scales, as harsh conditions destroy unprotected equipment and create safety hazards. Prime USA Scales stocks durable, dust and water-resistant bench scales that meet industrial demands and deliver reliable performance. Invest in your company’s future with scales that prevent costly errors, reduce the need for repairs, and minimize downtime.