If you run a company that processes its own orders in a warehouse, and you want to improve your output quality by weighing products before they get onto the truck, you’ve likely started looking into floor scales. After some searching, you’ve probably realized that your options here are abundant, and the variables that differentiate them can get a bit confusing.

Fortunately, you’ve come across this buyer’s guide to different types of industrial floor scales. In it, we will cover the various kinds of scales that exist and which key features you want to ensure that they have. That way, you can make a purchase knowing that you bought the right one.

The Different Types

When it comes to warehouse floor scales, you have a few different styles to choose from. Hopefully, one of them will pique your interest.

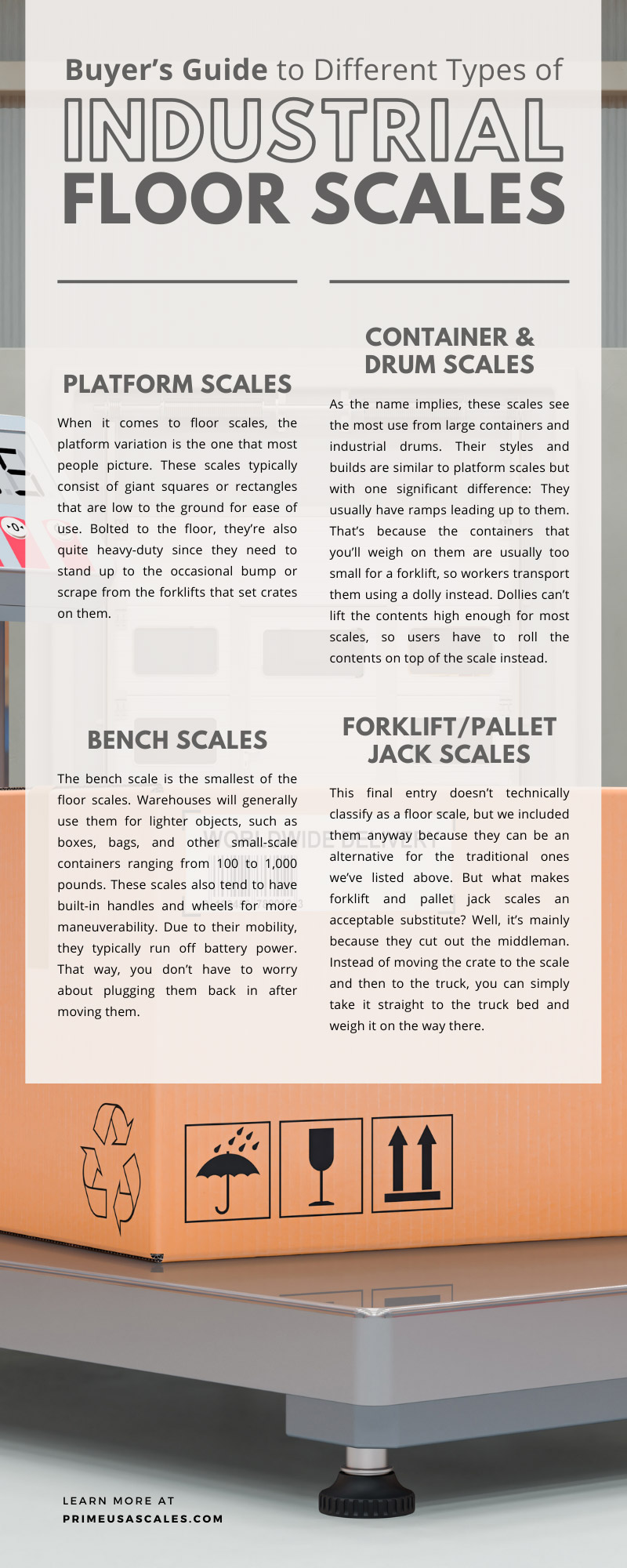

Platform Scales

When it comes to floor scales, the platform variation is the one that most people picture. These scales typically consist of giant squares or rectangles that are low to the ground for ease of use. Bolted to the floor, they’re also quite heavy-duty since they need to stand up to the occasional bump or scrape from the forklifts that set crates on them.

You can also use them to weigh livestock, which is another reason for their strong builds. In fact, since their capacities range from 500 to 20,000 pounds, their possible uses are nearly endless.

Container & Drum Scales

As the name implies, these scales see the most use from large containers and industrial drums. Their styles and builds are similar to platform scales but with one significant difference: They usually have ramps leading up to them.

That’s because the containers that you’ll weigh on them are usually too small for a forklift, so workers transport them using a dolly instead. Dollies can’t lift the contents high enough for most scales, so users have to roll the contents on top of the scale instead.

Bench Scales

The bench scale is the smallest of the floor scales. Warehouses will generally use them for lighter objects, such as boxes, bags, and other small-scale containers ranging from 100 to 1,000 pounds. These scales also tend to have built-in handles and wheels for more maneuverability. Due to their mobility, they typically run off battery power. That way, you don’t have to worry about plugging them back in after moving them.

Forklift/Pallet Jack Scales

This final entry doesn’t technically classify as a floor scale, but we included them anyway because they can be an alternative for the traditional ones we’ve listed above. But what makes forklift and pallet jack scales an acceptable substitute? Well, it’s mainly because they cut out the middleman. Instead of moving the crate to the scale and then to the truck, you can simply take it straight to the truck bed and weigh it on the way there.

Of course, this method isn’t perfect. Since the forklift will be in motion at the time, some inaccuracies are possible. Plus, you’ll only be able to weigh as much as the forklift or pallet jack can carry. That’s why these are best for busy warehouses. You can use them in a pinch, but you should still rely on your standard floor scales if you need precise measurements.

What To Look For in a Floor Scale

This buyer’s guide to different types of industrial floor scales has covered most of the important aspects of each variation, but there are a few key components that you’ll want to ensure that your scale has, regardless of the kind you get.

NTEP Approval

Anybody can claim that their scales are the most accurate on the market, but the only way to know for sure is if they have an NTEP approval rating. This rating is the grade a scale receives in accordance with your regional Weights and Measurements Department requirements. Without it, you’ll never know for sure if the items you weigh in your warehouse follow your local rules and regulations.

Plus, scales that have this rating typically have a higher quality and are more reliable, which will ensure that you’re getting your money’s worth in the long run.

High-Quality Parts

Of course, an NTEP rating isn’t the only way to determine a scale’s quality. You’ll also need to look at the parts the manufacturers used to make it. The exterior materials go a long way for preserving the sanctity of the scale, but its internal components are just as essential since they are the key to determining an object’s weight.

If the load cells or their cables are cheap, the accuracy of their inputs will quickly get worse with constant usage. Obviously, that’s not something you want out of such a vital piece of equipment.

Readout Capabilities

The information that the scale reads back to you is just as critical as the rest of it. For example, if your scale has an old-fashioned analog display, it’s going to be nearly impossible to tell which decimal place the total weight ends up being. That’s why you need a digital scale. If you want it to be as specific as possible, you can even get readers that extend past the second decimal number.

Of course, you’ll want it to have as many options as possible too. You never know which unit of measurement you need to label your next shipment, so a reader that can easily switch between ounces, pounds, grams, and even grains is incredibly useful. Any other valuable features it can offer would also be a plus.

Accessibility Features

Although the container and drum scales are the only ones that come standard with ramps to roll objects up easier, any of the other types can have them too. If you wish to create a more accessible warehouse, be sure to look for scales with preinstalled ramps, if possible.

The same thing goes with the mobility options we talked about for the bench scales. The other models can come with wheels and handles as well. You’ll just want to make sure that you can lock them in place after moving them. That way, they don’t start rolling away with thousands of pounds of products on them.