Industrial weighing scales are an indispensable tool across various sectors, including manufacturing, agriculture, logistics, and more. They ensure that the weight of raw materials, finished goods, and livestock is accurate, which is crucial for maintaining quality control, adhering to regulations, and optimizing operations.

Over the years, weighing technology evolved to deliver more precise and quicker results. The traditional mechanical weighing scales are now competing and sometimes working along digital scales.

Each type of scale has its distinct features, advantages, and drawbacks, making the choice between digital vs. mechanical industrial weighing scales a critical decision for businesses. Join us as we explore the differences between these two types of scales, their respective advantages, and which industries can benefit most from each.

Understanding Mechanical Weighing Scales

Mechanical weighing scales operate on the principle of equilibrium. These scales use springs, levers, and other mechanical components to measure weight. One of the key components is the spring, which deflects in proportion to the weight applied to the scale.

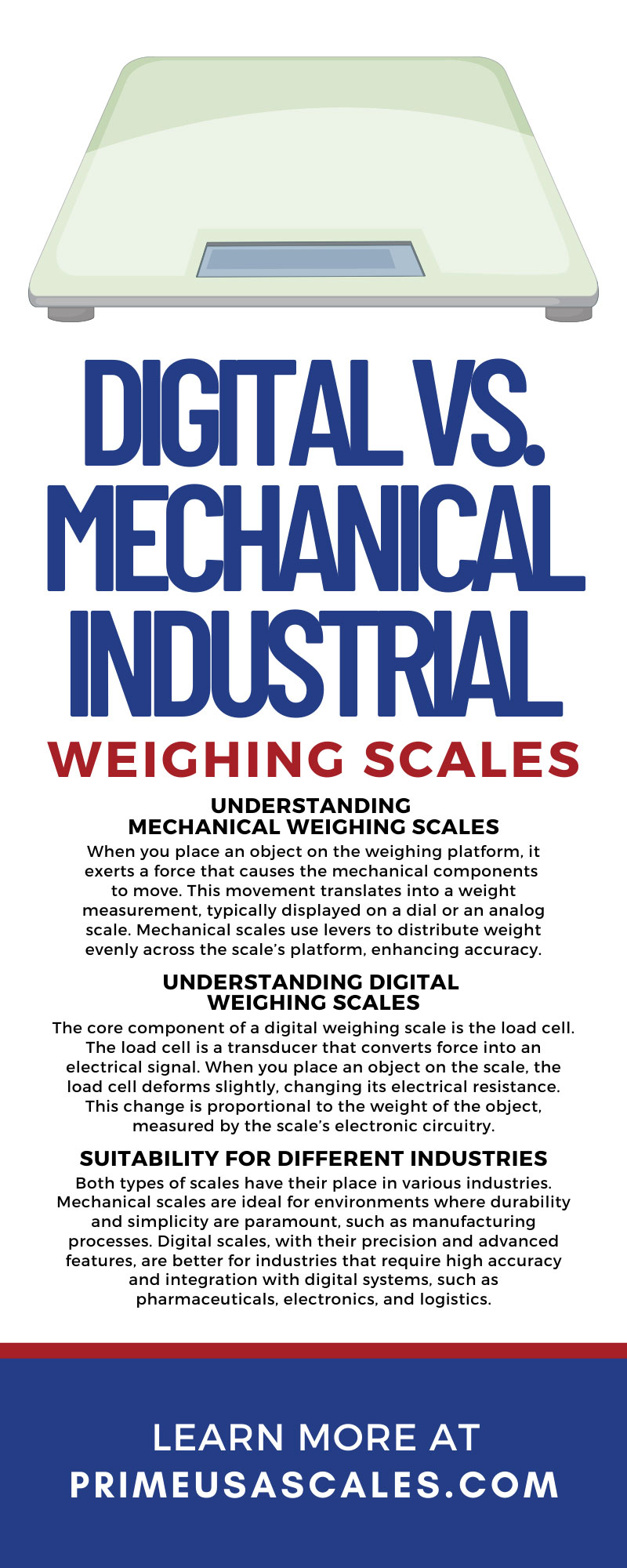

When you place an object on the weighing platform, it exerts a force that causes the mechanical components to move. This movement translates into a weight measurement, typically displayed on a dial or an analog scale. Mechanical scales use levers to distribute weight evenly across the scale’s platform, enhancing accuracy.

Advantages of Mechanical Weighing Scales

One of the primary benefits of mechanical weighing scales is their simplicity. With no need for batteries or electronic components, these scales can be incredibly durable and reliable, especially in environments where electricity is scarce or unreliable. These scales are more resistant to harsh environmental conditions such as dust, moisture, and extreme temperatures.

Since there are no electronic parts, there is minimal risk of circuit failure or software malfunctions. This efficiency leads to reduced downtime and maintenance costs, as mechanical scales require fewer repairs and calibration checks over their lifespan.

Limitations of Mechanical Weighing Scales

Mechanical scales have their own set of limitations. They can be less precise than their digital counterparts, especially when it comes to measuring very light or very heavy objects. Calibration can be more complicated and may require regular maintenance to ensure accuracy.

Readings can be more challenging to interpret accurately due to the analog display. These scales also tend to have slower response times compared to digital scales. It might take longer for the needle or pointer to settle, which can be a problem in fast-paced industrial environments where quick measurements are necessary.

Understanding Digital Weighing Scales

Digital weighing scales utilize electronic sensors to measure weight. These sensors convert the weight of the object into an electronic signal, processing and displaying it on a digital readout. This type of scale is common in various industries due to its accuracy, ease of use, and versatility.

The core component of a digital weighing scale is the load cell. The load cell is a transducer that converts force into an electrical signal. When you place an object on the scale, the load cell deforms slightly, changing its electrical resistance. This change is proportional to the weight of the object, measured by the scale’s electronic circuitry.

Advantages of Digital Weighing Scales

Digital scales offer several clear advantages over mechanical scales, accuracy being the most relevant. Many digital scales come with advanced features such as data recording, connectivity options, and the ability to interface with other digital systems, making them invaluable for modern industrial operations.

Another significant advantage is their efficiency and speed. Digital scales typically have faster response times than mechanical scales, particularly in high-volume settings where time is of the essence. They often come with user-friendly interfaces, programmable settings, and multilingual displays, making them accessible to a diverse workforce.

Limitations of Digital Weighing Scales

Despite their advantages, digital scales also have some drawbacks. They rely on electronic components and power sources, making them susceptible to electrical issues and power outages. Durability can be a concern in harsh environments where moisture, dust, and extreme temperatures are prevalent.

Maintenance and repairs can be more complex and specialized compared to mechanical scales. In environments where power sources are unreliable or nonexistent, digital scales may be impractical.

Suitability for Different Industries

Both types of scales have their place in various industries. Mechanical scales are ideal for environments where durability and simplicity are paramount, such as manufacturing processes. Digital scales, with their precision and advanced features, are better for industries that require high accuracy and integration with digital systems, such as pharmaceuticals, electronics, and logistics.

In industries such as agriculture, digital livestock scales are particularly beneficial. These scales can accurately measure the weight of animals, ensuring effective health and growth monitoring. Each industry benefits uniquely from the specific features provided by digital and mechanical scales, underscoring the importance of choosing the right type based on operational needs and environmental conditions.

Cost Considerations

When evaluating cost considerations, it’s essential to look beyond just the purchase price to truly understand the financial implications of both scales. For mechanical scales, the initial investment is usually lower due to their simpler construction and lack of electronic components. However, the ongoing costs can increase significantly due to the need for regular maintenance, calibration, and part replacements, especially in industrial settings where they endure heavy use and environmental stressors.

Digital scales often come with a higher initial price tag, reflecting their advanced technology and additional features, which results in substantial long-term savings. Digital scales generally require less maintenance and calibration, and their components tend to have a longer lifespan. Automation, data logging, and connectivity can streamline operations, reduce labor costs, and minimize human error, leading to enhanced overall efficiency and cost-effectiveness.

Selecting the Right Scale

Choosing the appropriate weighing scale depends largely on the specific requirements of the application. For environments requiring high durability and minimal maintenance, mechanical scales may be the better option due to their robust construction and longevity.

Digital scales are more suitable for applications demanding high accuracy and advanced functionalities. Learning the differences between digital vs. mechanical industrial weighing scales will help you select the most appropriate weighing scale, ensuring optimal performance and reliability.

By understanding the strengths and limitations of each type, you can make an informed decision that will enhance your operational efficiency and accuracy. Whether you prioritize durability or precision, there is a weighing scale solution that will meet your requirements and help you achieve your business goals.

Call us today to learn more about the best options for your weighing needs and explore our catalog of products to ensure your business benefits from the best scale.