Features:

- Dual-Range Accuracy to 0.01% FS: The ADT762W includes the unique ability to automatically switch between different internal calibrations depending on the current control pressure of the ADT762W. Additel provides calibrations unique to each ADT762W for ranges of 0-3,000 PSI (200 Bar) and 0-10,000 PSI (700 Bar), or 0-6,000 PSI (420 bar) and 0-15,000 PSI (1,035 bar). As the calibrator is pressurized, it will automatically select the control and measurement specification based on the specific pressure range. Pressure calibration range selection can be set to “auto” mode so the calibration range is automatically selected by the ADT762W based on the set point pressure, or the calibration range can be manually selected.

- Built-in Auto-Purge Application: Purging hydraulic calibration systems can be challenging and time consuming. The ADT762W has been designed with an integrated auto-purge system that saves time, money and frustration by completely automating the removal of air from the system. With the push of a button, the ADT762W quickly manages the system purging. This helps to free up time for technicians to attend to other needs.

- Dual-Port Manifold with Automatic Fluid Ex: When using hydraulic systems, we know that oils are a better lubricant and sustain the life of seals and components than water. But we recognize that for some applications, using oil is not an option. The ADT762W is designed to only be used with deionized water. The ADT762W has a built-in fluid management system to reduce standing water in the system which eases future maintenance requirements. The ADT762W should be used with the provided manifold which has a communication connection directly to the unit. This configuration is designed to extract residue water from the unit into the manifold after every vent. This function helps ensure the longest life of the unit and reduced maintenance costs.

- Documented Task Feature: The powerful documented calibration task application allows users to quickly create and execute tasks without the need for a PC or tablet. The ADT762W automatically analyzes errors, generates test reports, while storing results locally. The Additel 762W can support up to 1000 documented tasks which can be stored and recalled at any time to help save time and money.

- Dual-Mode Hart Communication: HART pressure transmitters can be directly maintained and calibrated without any other equipment or tools. The ADT762W provides an automatic HART calibration mode as well as a manual mode. This dual-mode HART communication function not only provides an efficient and convenient interoperability mode for DUT, but also supports access to a fully HART capable calibrator.

Specifications:

-

User Interface: Color touch screen and keypad operation

-

Display: 7” TFT touch screen 800 x 480 color

-

Enclosure IP Rating: IP31

-

Power: Dedicated lithium battery or power adapter

-

Battery: Rechargeable Li-Ion battery, typically 12 hours of operation, less than 5 hours recharge.

-

Weight: 28 lbs (12.8 kg) without media

-

Media: Deionized water

-

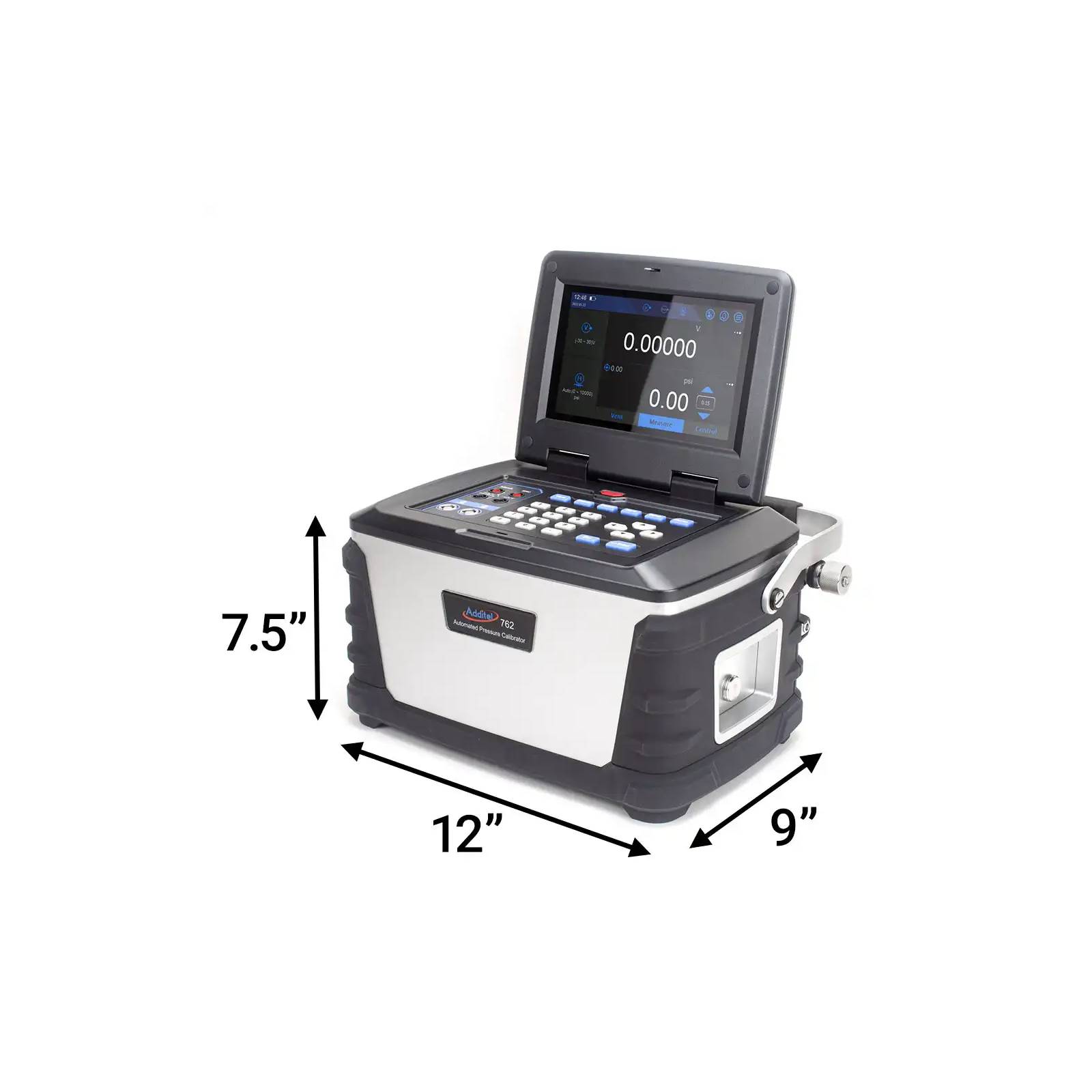

Size: 11.81 x 8.66 x 7.56 in (300 x 220 x 192 mm)

-

Communications: USB, LAN, Bluetooth, Wi-Fi and Ethernet

-

HART Communication: Read, configure and calibrate HART devices – DD files updated periodically

-

Data Storage:>8 GB

-

Data Logging: Up to 1,000,000 readings (data and time stamped)

-

Task Documentation: Up to 1,000 tasks can be stored with data

-

Automation Functions: Switch test, auto step, leak test

-

User Interface Localization: English, German, French, Italian, Spanish, Portuguese, Chinese, Japanese, and Russian

-

Pump Life: > 1,000,000 cycles

-

Environmental Specifications: Operating temperature: 32 °F to 122 °F( 0 °C to 50 °C)

-

Environmental Specifications: Storage temperature: -20 °C to 60 °C ( -4 °F to 120 °F)

- Environmental Specifications: Humidity: <90%, non-condensing

-

Certification: ISO 17025 accredited certicate of calibration with NIST-traceable data

-

Compliance: CE

-

Software Compatibility: ACal, Additel Land and Additel Link for access via mobile application

- Warranty: 1 year

-

Hose & Filter End of Life: The estimated End of Life (EOL) expectancy for all accessory hoses and filters (pneumatic and hydraulic) is approximately 10 years and should be replaced at the first sign of wear or damage.

Resources: