Key Features:

- Digital Weighing Auditor: Ensures that your balance is ready for use. It enables air buoyancy compensation in real-time. What is more, it informs about the need for a balance inspection or a periodic audit of the balance’s accuracy and sensitivity.

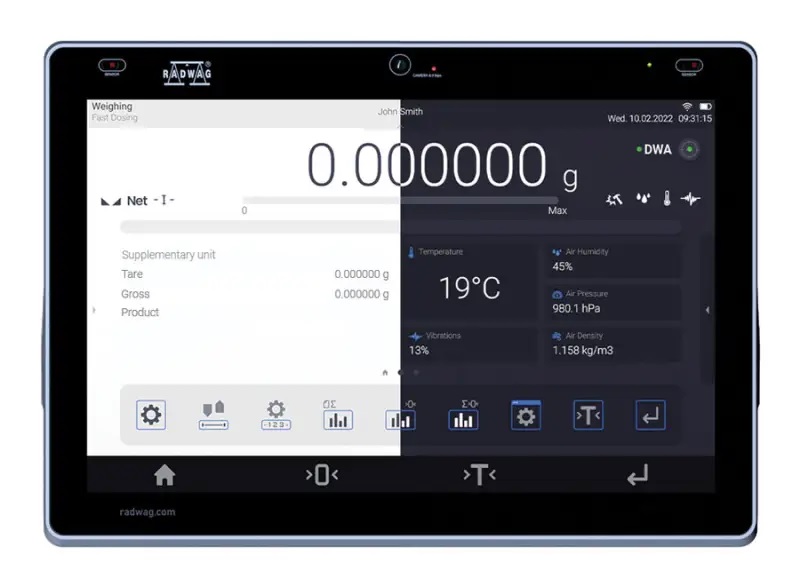

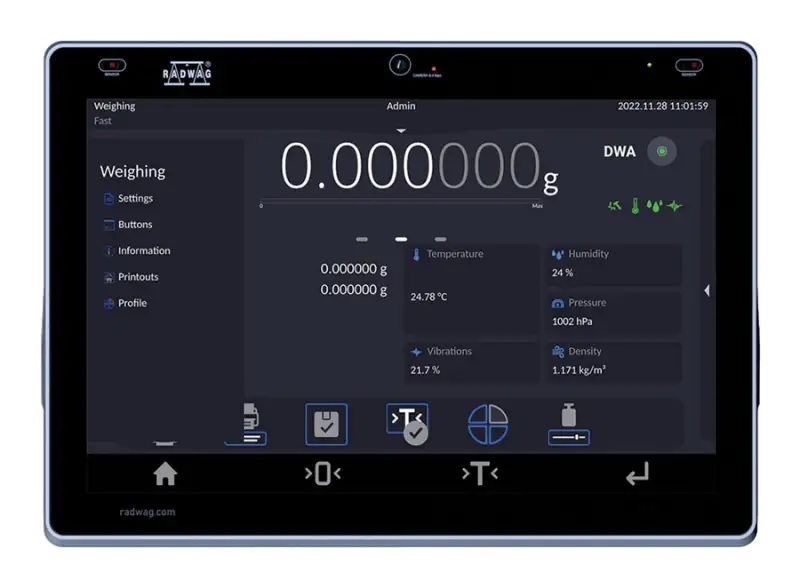

- 10-Inch Display: Bigger screen – 10’’ – means more information in one place. On the new ELLIPSIS terminal, you will see up to 3 screens, widgets, graphs, statuses, notes, handy measurement history.

- Uncompromising User Verification: For the first time ever, the balance will verify the user using a password, RFID card, fingerprint reader, facial recognition mechanism, or any combination of these.

- Ambient Light – An Innovative Way for the Balance to Communicate With the User: The light colour will tell you about status, process results, procedures, or alerts.

- Hotspot: Use the balance on any device connected to it. This can be a smartphone, tablet, or computer.

- RFID: ELLIPSIS works with RFID tags* that can be used to tag your products or formulation ingredients in the database. They can also be used to identify a user.

- Live Note – Note Down Your Conclusions: It’s the first time you can add a voice memo to a measurement series or procedure report. If you prefer to write it down, ELLIPSIS allows you to add a text note.

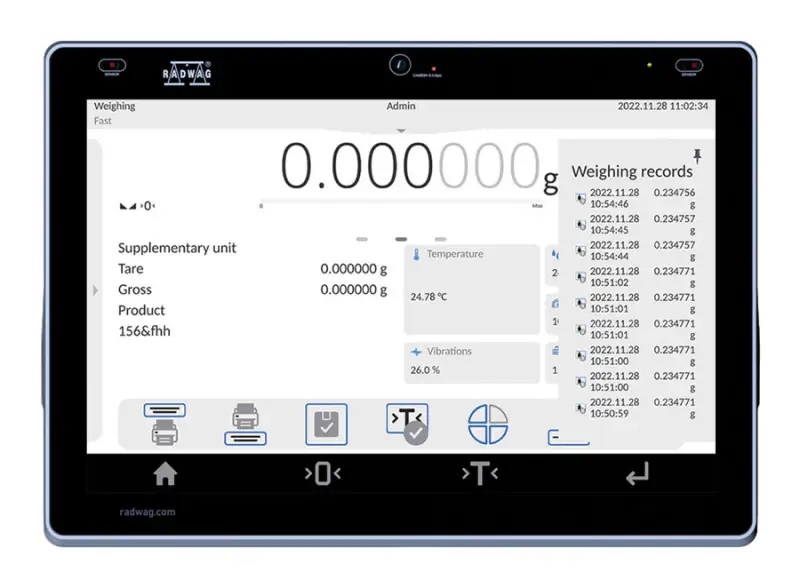

- Handy Library: This is where a series of recent measurements or a report ready for digital signature, according to 21 CFR Part 11, can be found.

- Widgets: Prepared to display what you need most at any given moment.

- Automatic Leveling of the Balance ReflexLEVEL System: Instead of manually leveling your scale – level it automatically. The ReflexLEVEL System saves you time and gives you maximum precision in your measurements.

- Smart Min Weight: The balance displays whether the value of the weight you want to weigh is below or above the minimum weight threshold.

- Two-point adjustment: Adjacency, which takes place at two measurement points instead of one, improves measurement precision over the full weighing range. And what does this mean for you? More accurate measurement.

Features:

- Ensures that your balance is ready for use.

- It enables air buoyancy compensation in real-time.

- Bigger screen – 10’’ – means more information in one place.

- The light colour will tell you about status, process results, procedures, or alerts.

- Use the balance on any device connected to it.

- This can be a smartphone, tablet, or computer.

- ELLIPSIS works with RFID tags* that can be used to tag your products or formulation ingredients in the database.

- It’s the first time you can add a voice memo to a measurement series or procedure report.

- If you prefer to write it down, ELLIPSIS allows you to add a text note.

- This is where a series of recent measurements or a report ready for digital signature, according to 21 CFR Part 11, can be found.

- Prepared to display what you need most at any given moment.

- Instead of manually leveling your scale – level it automatically.

- The ReflexLEVEL System saves you time and gives you maximum precision in your measurements.

Specifications:

- Model: UYA 2.5Y & UYA 6.5Y

- Maximum Capacity [Max]: 2.1 g, 6.1 g

- Minimum Load: 0.01 mg, 0.01 mg

- Readability [D]: 0.1 µg, 0.1 µg

- Verification Scale Interval [E]: 1 mg, 1 mg

- Tare Range: -2.1 g, -6.1 g

- Standard Repeatability [5% Max]: 0.15 µg, 0.2 µg

- Standard Repeatability [Max]: 0.35 µg, 0.45 µg

- Standard Minimum Weight (USP): 0.3 mg, 0.4 mg

- Standard Minimum Weight (U=1%, K=2): 0.03 mg, 0.04 mg

- Permissible Repeatability [5% Max]: 0.35 µg, 0.4 µg

- Permissible Repeatability [Max]: 0.6 µg, 0.8 µg

- Linearity: ±1.5 µg, ±1.5 µg

- Eccentric Load Deviation: 1.5 µg, 1.5 µg

- Sensitivity Time Drift: 1×10⁻⁶/Year×Rt, 1×10⁻⁶/Year×Rt

- Stabilization Time: 10 – 20 s, 10 – 20 s

- Adjustment: internal (automatic), internal (automatic)

- OIML Class: I

Physical Parameters:

- Leveling System: automatic – Reflex Level System, automatic – Reflex Level System

- Display: 10″ touchscreen, 10″ touchscreen

- Weighing Chamber Dimensions: ø90×90 mm, ø90×90 mm

- Weighing Pan Dimensions: ø16 mm, ø16 mm

- Packaging Dimensions: 655×755×445 mm, 655×755×445 mm

- Net Weight: 9.1 kg, 9.1 kg

- Gross Weight: 16.6 kg, 16.6 kg

Included with Scale:

- Ultra-microbalance

- Terminal

- Weighing pan

- Weighing pan shield

- Glass lid

- Power supply

- Anti-draft shield

- Pincette

- Brush

- Fabric Dust Cover

Communication Interface:

- USB-A ×2

- USB-C

- HDMI

- Ethernet

- Wi-FiHotspot

Electrical parameters:

- Power Supply: Adapter: 100-240V AC 50/60Hz 1A; 15V DC 2,4A

- Balance: 12 – 15V DC 1,4A max*

- Adapter: 100 – 240V AC 50/60Hz 1A; 15V DC 2,4A

- Balance: 12 – 15V DC 1,4A max*

Environmental conditions:

- Operating Temperature: +10 — +40 °C, +10 — +40 °C

- Operating Temperature Change Rate: ±0.3°C/1h (±1°C/8h), ±0.3°C/1h (±1°C/8h)

- Relative Humidity: 40% — 80%, 40% — 80%

- Relative Humidity Change Rate: ±1%/h (±4%/8h), ±1%/h (±4%/8h)

Modes:

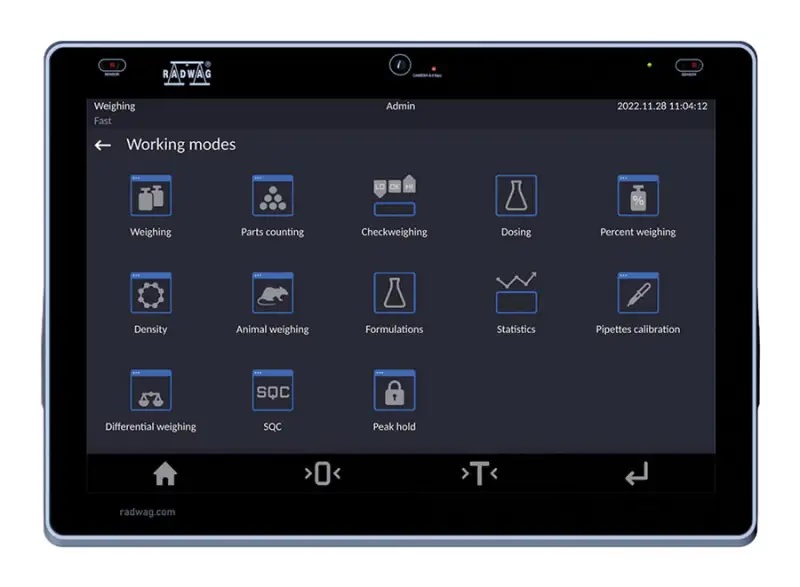

- Weighing – Basic working mode that displays the mass of a sample

- Parts counting – Quick counting of samples of similar mass

- Checkweighing – Control of sample mass in the set min/ max thresholds

- Dosing – Weighing to a target value

- Percent weighing – Percent mass control

- Density – Determining the density of solids and liquids

- Animal weighing – Control of mass change over a set period of time

- Formulations – Weighing of predefined ingredients, according to the order described in the formulation

- Statistics – Real-time statistics determined from carried out weighings

- Pipette calibration – Checking piston pipettes according to customer-specific requirements or ISO 8655

- Differential weighing – Analysing the change in mass of a single sample over time

- SQC – Statistical mass control with set thresholds

- Peak hold – Control of the maximum mass on the pan

- Mass control – Statistical control of samples of similar mass

- Comparator – Control of mass standards

- PGC – Statistical mass measurement in accordance with Packaged Goods Control

Functions:

- Autotest

- Dosing

- Percent Weighing

- Parts counting

- Peak hold

- Formulation

- Statistics

- Checkweighing

- IR sensors

- GLP Procedures

- Animal weighing

- Pipettes Calibration

- Air density correction

- Density determination

- Differential weighing

- Ambient conditions monitoring

- Statistical Quality Control

- Packaged Goods Control

- ALIBI Memory

- Wi-Fi®

Resources: