Precision is crucial in various sectors to deliver accurate results and achieve constant development. This is more noticeable in industries where platform scales are pivotal for daily operations. A reliable platform scale does more than just weigh objects. It ensures that businesses meet compliance standards, safeguards against costly errors, and fosters customer trust through consistent and correct measurements.

However, even the most reliable scales can sometimes deliver inaccurate results. Learning the reasons your platform scales may be inaccurate will help you troubleshoot possible problems and maintain the operational efficiency of your business.

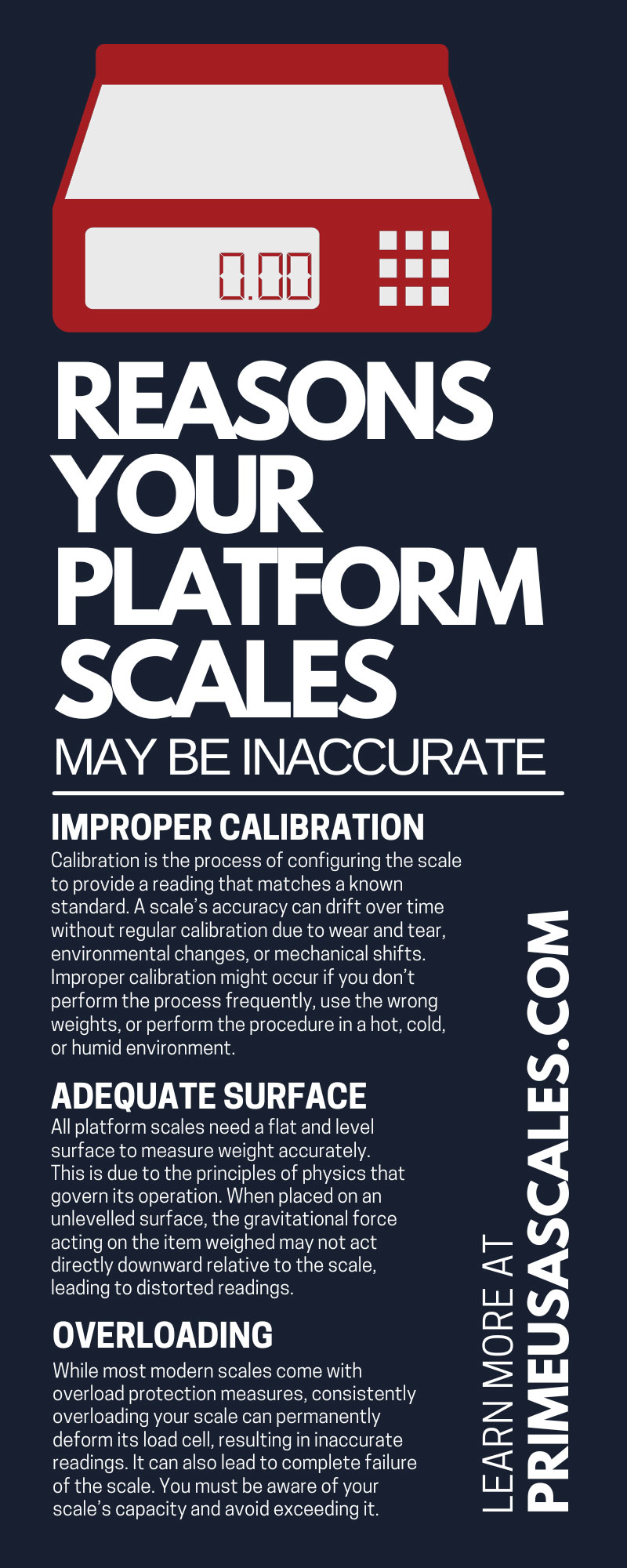

Improper Calibration

Calibration is the process of configuring the scale to provide a reading that matches a known standard. A scale’s accuracy can drift over time without regular calibration due to wear and tear, environmental changes, or mechanical shifts. Improper calibration might occur if you don’t perform the process frequently, use the wrong weights, or perform the procedure in a hot, cold, or humid environment.

A trained professional should perform this calibration using certified calibration weights to ensure the highest level of accuracy. Operators must establish a routine calibration schedule and strictly adhere to it; failure can lead to significant inaccuracies and costly mistakes.

Adequate Surface

All platform scales need a flat and level surface to measure weight accurately. This is due to the principles of physics that govern its operation. When placed on an unlevelled surface, the gravitational force acting on the item weighed may not act directly downward relative to the scale, leading to distorted readings.

This problem becomes even more pronounced in high-precision applications or when weighing heavy objects. To ensure your scale is level, use a spirit level when setting it up. Industrial platform scales come equipped with unique features, like adjustable feet, to correct minor variations in the surface level.

Overloading

Platform scales function optimally within a certain weight range, specified as the scale’s capacity. This capacity outlines the maximum load a scale can manage without damaging its components. Overloading occurs when you place a weight beyond this specified capacity.

While most modern scales come with overload protection measures, consistently overloading your scale can permanently deform its load cell, resulting in inaccurate readings. It can also lead to complete failure of the scale. You must be aware of your scale’s capacity and avoid exceeding it.

Temperature Fluctuations

Most scales operate within a specific temperature range, and any deviation from this can lead to inaccurate measurements. This is because temperature changes can cause materials to expand or contract, including the internal mechanisms of the scale.

Operating your scale in a stable, temperature-controlled environment is necessary. If you can’t avoid using the scale when temperature changes are frequent, consider investing in scales that can withstand such conditions.

Aging Components

Like any piece of equipment, platform scales can experience wear and tear over time. Components can become worn out, connections can become less secure, and even the platform can become slightly warped or corroded, especially if you use the scale in harsh environments.

This deterioration can negatively impact the accuracy of the scale’s measurements. Regular maintenance and inspections are crucial to identify signs of aging and worn-out parts immediately. Even with the best care, components will eventually need replacements.

External Vibrations

External vibrations from various sources can significantly interfere with the accuracy of a platform scale’s readings. These vibrations could come from multiple sources, such as nearby operating machinery, heavy vehicular traffic, or even high winds in some instances.

The oscillating movement from these vibrations can disturb the scale’s stability, causing the readings to fluctuate and leading to inaccuracies. To counteract these effects, try to place your scale in a location where external vibrations are minimal.

Dust and Debris

Over time, dust, grime, and other particles can accumulate on the platform or beneath the weighing pan, causing the scale to give a higher reading. This issue is especially prevalent in industries that use scales in dusty or outdoor environments, such as construction or agriculture industries.

Regularly cleaning the scale, including the weighing surface and underneath the weighing pan, can ensure accurate measurements. By maintaining a clean weighing environment, you can enhance the longevity and accuracy of your platform scale.

Electrical Interference

Electrical interference, also known as electromagnetic interference (EMI), can significantly impact the accuracy of platform scales. Nearby electronic devices, power lines, or even fluorescent lighting can generate electromagnetic fields that disrupt the electrical components of the scale.

These disruptions can cause the load cell to produce inaccurate readings, leading to inconsistent weight measurements. Severe EMI can even cause permanent damage to the scale’s internal circuitry. To mitigate the effects of electrical interference, try to place your scale away from strong energy sources.

Inadequate Power Supply

An inadequate power supply can affect the proper functioning and accuracy of digital platform scales, which is one reason your scales may be inaccurate. These scales require consistent and stable power to deliver accurate readings and maintain their electronic components’ optimal performance.

Any fluctuations in the power supply, such as voltage spikes, power surges, or brownouts, can lead to inconsistent measurements and potentially even damage the scale. To prevent platform scale inaccuracies, regularly inspect the power cords and outlets for any signs of wear and tear or damage, as they could also compromise the power supply.

Using the Wrong Type of Scale

The issue of using the wrong type of scale predominantly revolves around attempting to measure weights that are either too light or too heavy for the specific scale in use. Each scale manages a certain weight range; using it outside these parameters can lead to significant inaccuracies in readings.

If you use a scale designed for lighter weights to measure heavier items, the scale’s capacity will fail. This can strain the scale’s load cells and lead to permanent distortion, impacting the scale’s accuracy and performance in the long run.

Many factors influence the accuracy of platform scales. By adhering to the manufacturer’s instructions for use and regularly checking the scales for signs of aging or damage, you can ensure their accurate and reliable functioning. Regular calibration and maintenance of your platform scales are necessary. You must implement a consistent maintenance schedule and regularly check your equipment.

Call us today to learn more about platform scales and find the right options for your business to ensure accurate readings. If you need professional maintenance, we can restore your scale to its optimal condition to ensure business success.