Livestock scales serve as a foundation for accurate decision-making across agricultural operations. Producers rely on precise weight data to manage animal health, track growth, plan feed programs, and determine fair market value. When dirt, mud, manure, or debris accumulate on weighing equipment, accuracy declines and operational risks increase. The importance of keeping livestock scales dirt-free cannot be overstated, as doing so protects data integrity, equipment performance, and daily productivity.

Clean scales also reflect professionalism and operational discipline. They support safer handling, reduce maintenance costs, and help operations meet industry expectations. Consistent cleaning practices turn a simple task into a powerful tool for long-term success.

Cleaning Livestock Scales Ensures Accurate Weight Measurements

Accuracy is the primary reason to maintain clean scales. Dirt buildup interferes with how weight distributes across the platform and load cells. Even minor debris trapped under a scale can alter readings enough to affect health treatments, feeding adjustments, and sale weights.

Producers use weight data to make time-sensitive decisions, but inaccurate readings delay interventions and increase financial risk. Clean livestock scales provide consistent measurements that operators can trust. This reliable data improves planning and eliminates uncertainty during weighing sessions.

Keeping Scales Dirt-Free Protects Components From Damage

Dirt acts as an abrasive and moisture trap, which means mud and manure hold water against steel decks, load cells, and cables, accelerating corrosion and wear. Over time, that exposure shortens component life and increases repair frequency.

Routine cleaning removes debris before it damages critical parts. Clean surfaces allow load cells to flex correctly and prevent strain on wiring and connectors. By protecting internal components, producers extend the life of their equipment and preserve its performance.

Specifically, electronic components play a critical role in modern livestock scales. Indicators, junction boxes, and connectors rely on clean, sealed environments to function correctly, but dirt and moisture intrusion cause signal interference and inconsistent readings.

Keeping these areas clear protects sensitive electronics and reduces troubleshooting time. Clean connections also ensure stable communication between components and support accurate weight display during every use.

Cleaning Scales Promotes Safer Livestock Handling

Animal safety depends on stable and predictable equipment. Dirt and manure create slick or uneven surfaces that can cause animals to slip, hesitate, or resist movement. Those reactions increase stress and raise the risk of injury for both livestock and handlers.

Clean platforms provide better traction and more familiar footing. Animals move across clean scales more calmly, which speeds up the weighing process and reduces handling pressure. Ultimately, a dirt-free scale supports humane handling practices and smoother workflows.

Keeping Scales Clean Reduces Downtime and Disruptions

Unexpected scale issues slow operations and disrupt schedules. Dirt-related problems often appear during busy periods, such as shipping, health checks, or inventory counts. Debris around load cells or connectors leads to errors that require troubleshooting or service calls.

Regular cleaning helps operators identify small issues early, as clear access to components simplifies inspections and maintenance. Clean livestock scales remain operational for longer, reduce downtime, and keep teams focused on productive tasks.

Maintaining Dirt-Free Scales Supports Regulatory Compliance

Many operations rely on accurate weights for inspections, certifications, and commercial transactions. Dirty equipment raises concerns about reliability and process control. Inspectors and buyers expect weighing equipment to remain clean and well maintained.

Maintaining clean cattle scales demonstrates attention to detail and a commitment to accurate measurements. Doing so also protects credibility during audits, reduces disputes during sales, supports compliance, and reinforces trust in reported weights.

Cleaning Scales Improves Operational Efficiency

Efficiency drives profitability, which means clean livestock scales streamline daily workflows by reducing reweighs, corrections, and delays. Operators move animals through faster when equipment performs consistently and safely.

Trustworthy scale data improves coordination across teams. Feeding plans, shipping schedules, and inventory records depend on accurate weights, and clean scales eliminate confusion and support smoother communication throughout the operation.

Cleaning Consistently Extends Scale Lifespans

Livestock scales are a significant investment, and protecting that investment starts with routine care. Simple cleaning habits prevent long-term damage and reduce unexpected repair costs.

Effective scale cleaning routines often include:

- Removing visible debris after each weighing session

- Washing platforms with low-pressure water when buildup appears

- Inspecting load cells, cables, and connectors during cleanings

- Allowing components to dry fully before use

These actions take little time but deliver lasting value, as clean livestock scales provide dependable data that drives smarter decisions across animal health, nutrition, and marketing. Accurate weights reveal performance trends and help identify issues early, allowing producers to act quickly and confidently.

Clean equipment also reflects a commitment to quality and professionalism. Buyers, inspectors, and partners notice well-maintained tools. Clean scales reinforce trust in your operation and the numbers you provide.

Keeping Scales Clean Maintains Accurate Calibration Results

Calibration ensures a scale delivers precise readings over time, but dirt interferes with proper load distribution during calibration checks and leads to inaccurate adjustments. Technicians need clean equipment to verify performance accuracy.

Operators who maintain dirt-free livestock scales between service intervals experience more stable calibration results. Clean equipment holds accuracy longer and reduces the need for repeat service visits. This reliability saves time and supports confidence in recorded data.

Maintaining Dirt-Free Equipment Reduces Wear and Corrosion

Outdoor installations face constant exposure to rain, dust, bedding material, and manure. Environmental buildup accelerates corrosion and compromises a scale’s seals and connectors. Seasonal changes often increase debris accumulation, especially during wet or muddy conditions.

Routine scale cleaning limits moisture retention and slows corrosion. By removing debris before it settles, producers protect the scale’s steel decks and electronic components. Clean equipment withstands harsh environments more effectively and performs reliably year-round.

Talk With the Experts About Proper Livestock Scale Care

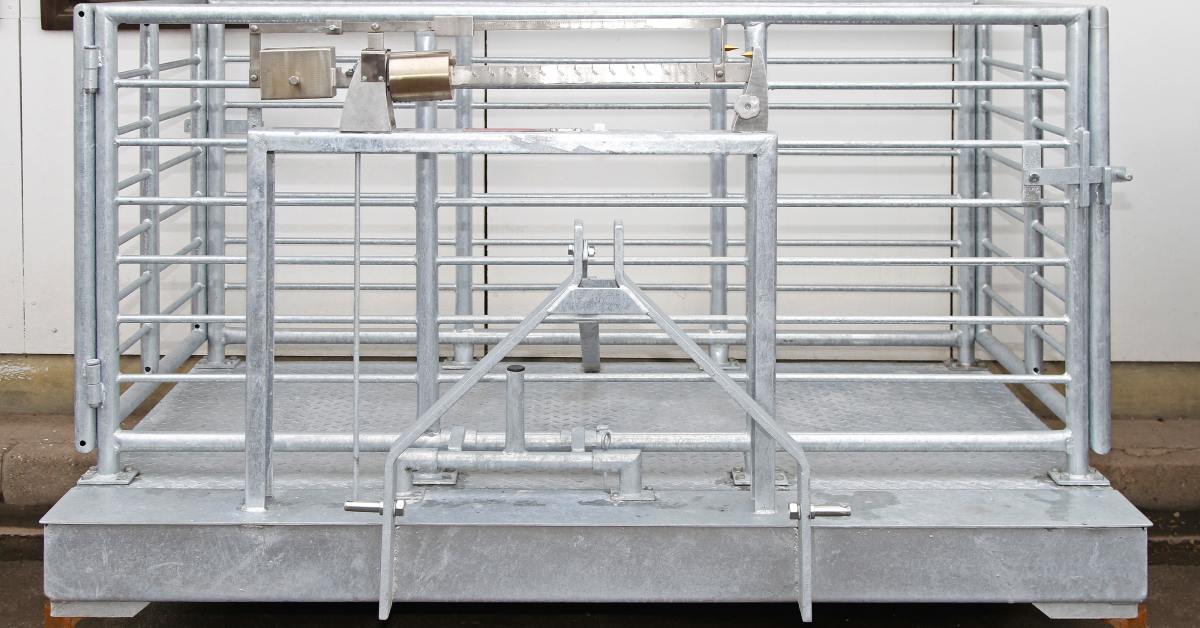

Keeping livestock scales dirt-free improves weighing accuracy, worker and livestock safety, and equipment longevity. If you want guidance on maintenance best practices or need durable scales built for demanding environments, expert support makes a difference.

At Prime USA Scales, we provide high-quality weighing solutions, nationwide service, and industry expertise to help operations maintain reliable performance. Contact our team today to discuss your needs and get the right livestock scale for the job.