Accurate weight measurements are the foundation of many industrial operations, where every gram can influence product quality, safety, and cost-efficiency. In industries ranging from manufacturing to shipping, the choice of a floor scale can influence the accuracy of measurements and impact operational flow, space management, and even worker safety.

A durable, well-functioning scale ensures your business can maintain consistency in its products, comply with regulations, and optimize its processes. These tips for choosing the right industrial floor scale prioritize important industry features and can help you identify a floor scale that’s as resilient and reliable as your business.

Consider the Weight Capacity

Selecting a floor scale with an appropriate weight capacity ensures your operations run smoothly without risking equipment damage or inaccurate readings. Make sure that the scale you choose can handle your heaviest loads with ease. But also remember that excessively high capacities might reduce the sensitivity you need for smaller items.

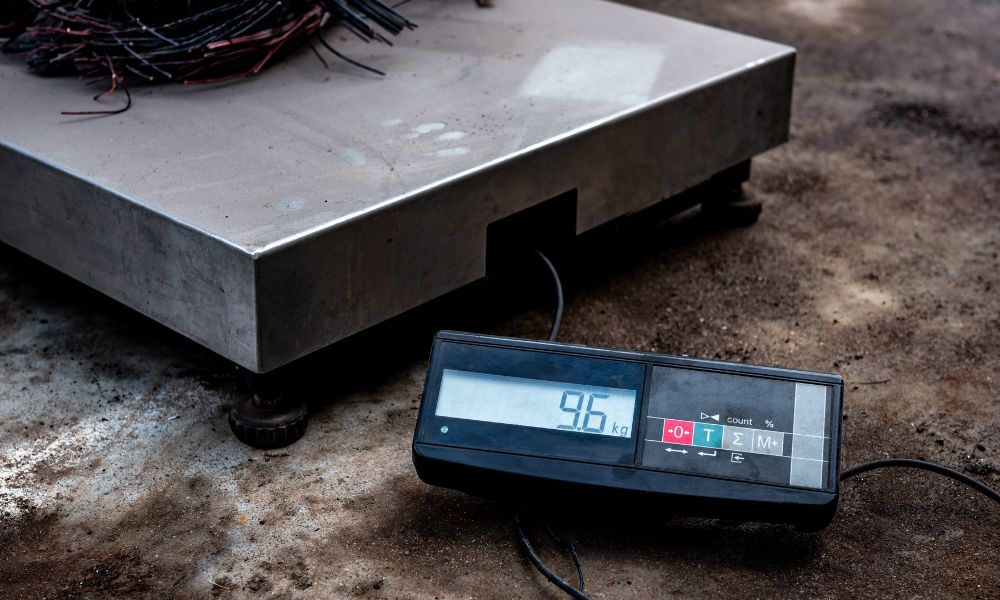

Assess Durability and Material

Industrial environments can be harsh, and your floor scale will need to withstand a good deal of wear and tear. Choose a scale with high-quality materials that offer durability. Stainless steel scales are the go-to choices for many industries due to their resistance to corrosion and ease of cleaning. The sustainability of your floor scale directly impacts its lifespan and, consequently, your return on investment.

Select Appropriate Features and Options

Think about the additional features that can make your weighing process more efficient. Modern platform scales come with a variety of options, such as ramps for easy loading, built-in printers for immediate documentation, or wireless capabilities for seamless data integration. Tailoring your floor scale’s features to fit your specific operational workflow can greatly enhance productivity.

Verify the Scale’s Accuracy

Accuracy in weight measurements is nonnegotiable in industrial settings. Every gram matters, as even the slightest inaccuracy can lead to significant discrepancies over time. Confirm the accuracy specifications of the scale at different weight intervals and ensure it aligns with your business’s operational needs. It’s also vital to establish a regular calibration routine to maintain that accuracy over the scale’s life.

Evaluate the Environment of Use

Your operational environment can significantly influence the type of floor scale you should choose. If your business deals with food, chemicals, or any other sensitive materials, you must consider scales designed for hygienic and easy-to-clean purposes. If you need to use the scale outdoors or in rugged conditions, look for a more robust option with appropriate environmental seals.

Choosing the right industrial floor scale is a strategic decision that affects your business’s operational efficiency and accuracy. By considering these factors, you can select a scale that meets your current needs and supports future growth.

Call us today to find the perfect weighing solution tailored to your unique requirements. Let us help you weigh your options and provide you with a durable, accurate, and feature-rich scale that’ll serve your business for years to come.