Businesses that rely heavily on weight and transportation, like warehouses, need solutions to help them successfully achieve their goals. Various products in the market can deliver more than one function to save time, money, and space.

Every industry has a standard process that helps a business with consistent results and could increase productivity and deliverables. The right products and services will transform a business, and one element could impact and improve every process.

A pallet wrapper scale benefits your business for different reasons; these machines can multitask and provide services like no other. Building a safe environment while working with heavy-duty machinery and heavy objects will have a positive outcome in every possible way.

What’s a Pallet Wrapper Scale?

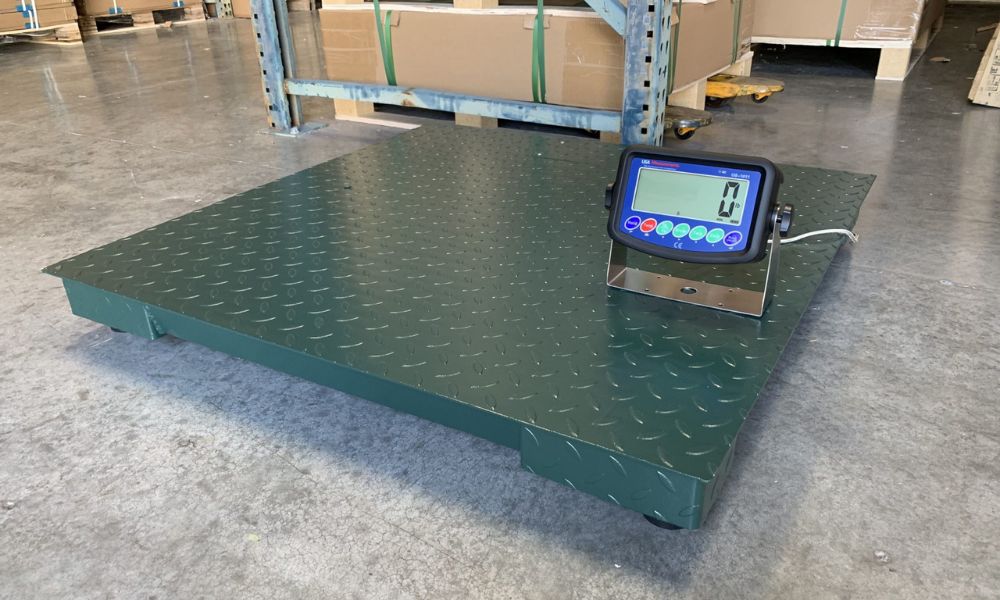

Moving products inside a warehouse for storage and production is necessary to improve storage space and moving times. A pallet wrapper scale is a machine with a rotatory base that wraps products on top of a pallet with plastic to add protection.

Wrapping and weighing products simultaneously is an excellent way to ensure that the count and size are correct, especially when loading a truck to transport them. This type of scale makes it simpler to get accurate numbers and get products ready for shipping and delivery.

Increase Safety

Increasing safety for products and workers inside a warehouse and while transporting these products is essential. Wrapping certain products and boxes with plastic will decrease damage due to shipping and rough handling. Time is essential in warehouses, and sometimes dealing with many products could get challenging; however, with the right preparation, everything will stay safe and secure.

Accidents could happen anytime, and the right elements will decrease the risk of something breaking or someone getting injured. A pallet wrapper scale is a reliable and easy way to secure irregular shapes, different sizes, weights, and materials.

Transportation Stability

Weight is important for trucks and transportation because it helps the vehicle balance, calculate speed, and enhance interior space. Shipping products is a necessary process for any industry, and ensuring that everything travels safely from one location to another will make a big difference.

Getting the right weight distribution added to protection elements like wrapping plastic is a simple way to effectively deliver consistency. You will get a greater return on investment because one scale will allow you to wrap and weigh multiple products in less time and with greater accuracy.

Simple To Use

Pallet scales that wrap products are straightforward machines that require proper handling of products, but technology makes them easier to manage. With everything in place, this type of scale makes the process simple and effective for any product, including irregular shapes.

Weighing scale manufacturers understand that simple processes help businesses increase productivity that benefits everyone, including manufacturers. Technology plays a large role in developing new products and allows industries to get ahead of the competition by employing best practices.

Increase Productivity

Combining activities into one process will allow you to focus on other aspects of the products or your warehouse, like delivery times, transportation, and enhancing techniques. With machines getting more involved in human processes, warehouses can decrease production time and increase the efficiency of processes.

Most businesses aim to cut time in half and produce more results while reducing human involvement in various activities. Before, a group of people would need to weigh the final products and then transition into wrapping it; thanks to pallet wrapping machines, this can now be achieved with just one machine.

Precision and Management

Effective wrapped and managed products get better results through different activities, such as easier handling. A scale will deliver precise results thanks to advanced sensors that distribute the weight evenly to get more accurate numbers. Wrapping a finished product with reliable materials with versatility and strength will get better acceptance.

A wrapper pallet scale will benefit your business with high-quality results that will elevate your process to meet customer and business needs. Having the necessary equipment in your warehouse gives you the freedom to decide what product to use, choose a better process, and make informed decisions.

Reduce Labor Costs

Having the right team with sufficient preparation to deal with and manage equipment and machinery will reduce your labor cost and increase revenue. Saving money and investing in new ways to increase productivity is a strategy most businesses need to stay on top of the competition.

Labor cost is one of the main lines that industries deal with, aside from dealing with insurance policies, safety, and retirement plans. Machines can do most jobs, and while that requires an initial investment, it’s one your business can recuperate quickly with the right process.

Focus on Other Activities

When a machine is reliable and accurate, it gives you the freedom to focus your attention on other elements that could have weak spots. Owning or managing a business like a warehouse means that you must find the best options to keep production and processes going strong.

Wrapper scales come in standard sizes that can deal with any type and size of products while staying safely out of the way. That way, workers can focus on other activities, making every process work more efficiently to bring them all to the same level of excellence.

Transportation Options

There is not just one way to transport products; you can choose between different vehicles to ensure that the products get to their destinations in a timely manner. Using trucks to transport products requires certain weights and characteristics to ensure that everything goes smoothly. Airplane transportation is another aspect you must consider when necessary.

Airports have stronger regulations about weight because airplanes can only take a certain amount of cargo weight. Industrial scales deliver accurate results, which is why airports have them; meeting those weight expectations without making changes will save you time, money, and stress.

Custom Wrapping

The different products that a wrapping pallet scale works with require different characteristics that this machine will help you achieve efficiently. Irregular items require special wrapping that ensures every inch and corner gets the protection it needs.

Custom wrapping allows you to choose the amount of plastic wrap to use for individual or group packages. This option will let you budget and plan how much to spend on ensuring product quality.